PROBLEM STATEMENT

Generator repair is required to keep power plants operating at peak performance.

PROJECT HIGHLIGHTS

Our customer required that we design a 400T system of jacking and support equipment capable of removing the rotor and subsequently re-installing the refurbished rotor that included:

- 400T total capacity.

- Adjustable position of the spigot plates to allow the beams to engage generators that have varying space on their lifting lug locations.

- Total jacking height designed to allow the stator core to be pushed from the generator casing and onto stator core support stools (built by Unified) along the maintenance rails of the core.

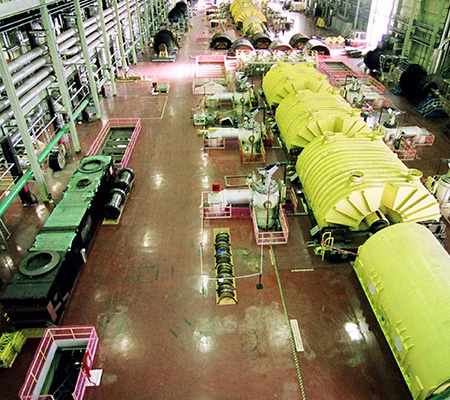

Generator Jacking Beam System Designed for Power Plants Peak Performance

This jacking beam system was designed to engage the sides of the generator casing and permit the use of hydraulic jacks to incrementally jack the generator casing above the turbine deck for stator core removal.

The one picture shows a close shot of one of the jacking beams bolted to the side of the generator casing. The hydraulic cylinders (near and far end of the beam) are collapsed and ready to make the next incremental jacking stroke (approximately 11” at a time).

At full stroke, additional pieces are added to the three support stools along the length. Then, the jacks are retracted, removed, and another piece of the jacking stool is added at the two jack locations. The jacks are then reinstalled for the next incremental jacking stroke.

Outcome: Project was completed safely, on time, on budget, and to specification conforming to contract requirements and with good workmanship.

Highlights: Ability to do turnkey engineering and manufacturing of a lifting and jacking system to progressively remove the generator rotor and stator.

We take complete responsibility for the project from conceptual design, and engineering analysis through to creating fabrication drawings and following through with the fabrication build portion.

WORK WITH US

Unified takes on the full turnkey engineering design and build responsibility. One source, one responsibility.